Products

“TOPCLEAN” offers three types of fluorescent tube waste shredding equipment to meet the needs of different types of fluorescent tubes as well as the capacity required.

TOPCLEAN is designed to accommodate the collection / treatment capacity at general industrial waste disposal service providers. Its compact size and reasonable price are recognized by a number of customers.

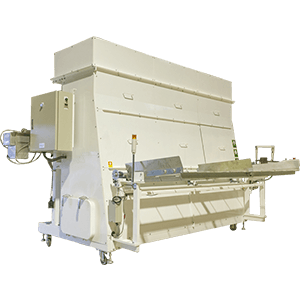

TOPCLEAN Type-1 - 40W/110W WASTE FLUORESCENT TUBES SHREDDING EQUIPMENT

This type of equipment will treat straight-type fluorescent tubes waste with different lengths (40W and 110W) at the same time. By taking out the capacity for 20W tubes, which are not commonly used, from the conventional model, its capacity has been significantly improved to 1,500 pieces per hour.

Main features

Separated shredding of glass covers and mouthpieces

With the conventional type of waste fluorescent tubes shredding equipment, manual operation is required to separate glass covers and mouthpieces, which may cause environment and/or safety issues as mercury may be scattered or evaporated from fluorescent powder during such manual work.

With our product, 40W and 110W straight-type fluorescent tubes will be shredded into glass covers and mouthpieces automatically and sent to different containers through screw conveyors. Eliminating manual operations will ensure both environmental and operational safety.

Other features to ensure clean working environments include an in-built dust collector which collects dust caused by shredding, absorbs the dust with a filter and active carbon and discharges it to the air eventually, as well as the outlet covers which ensure any glass covers and mouthpieces separated will not be scattered *1.

The length of fluorescent tubes to be treated (40W / 110W) can be switched with a lever on the back side of the equipment.

*1 In the photos posted on this website, these covers may be removed so that you can see the detailed parts of the equipment.

1,500 pieces/hour high-speed operation

The maximum treatment capacity of the conventional type of waste fluorescent tubes shredding equipment manufactured by other company is at most 1,000 pieces per hour, without separating glass covers and mouthpieces.

On the other hand, our product can shred 1,500 pieces of fluorescent tubes (or 375 kg of 40W straight-type tubes) per hour, while separating glass covers and mouthpieces. You may be concerned that if the equipment is operating at such high-speed, it would cause scattering glass pieces and mouthpieces, which results in failure and poor durability. This is not the case for our product.

We have been manufacturing fluorescent tubes waste shredding equipment for 17 years. We have delivered to many handlers of industrial waste so far and have made a series of improvements of our products by listening to our customers. As a result of this, we have achieved high-speed operations reaching 1,500 pieces per hour, while maintaining high durability.

Easy operations / Automatic shutoff

With the conventional type of fluorescent tubes waste shredding equipment, it is required to constantly feed fluorescent tubes waste to the tray and monitor containers where shredded glass pieces and mouthpieces are sent. This means that an operator has to move from the front to the back of the equipment and switch operations. It is inefficient and there seems to be many cases that two operators are assigned.

Our product is equipped with an easy-to-use large operating switch which is designed by taking the traffic line of operators into account and subsequently improve operational efficiency. With this switch, it is also enabled to set the number of fluorescent tubes to be shred so that the equipment should automatically stop when reaching the set number. As a result, an operator is not required to monitor the containers anymore but may focus only on feeding waste fluorescent tubes into the equipment. This will contribute to not only improvement of operational efficiency but also elimination of manual operations.

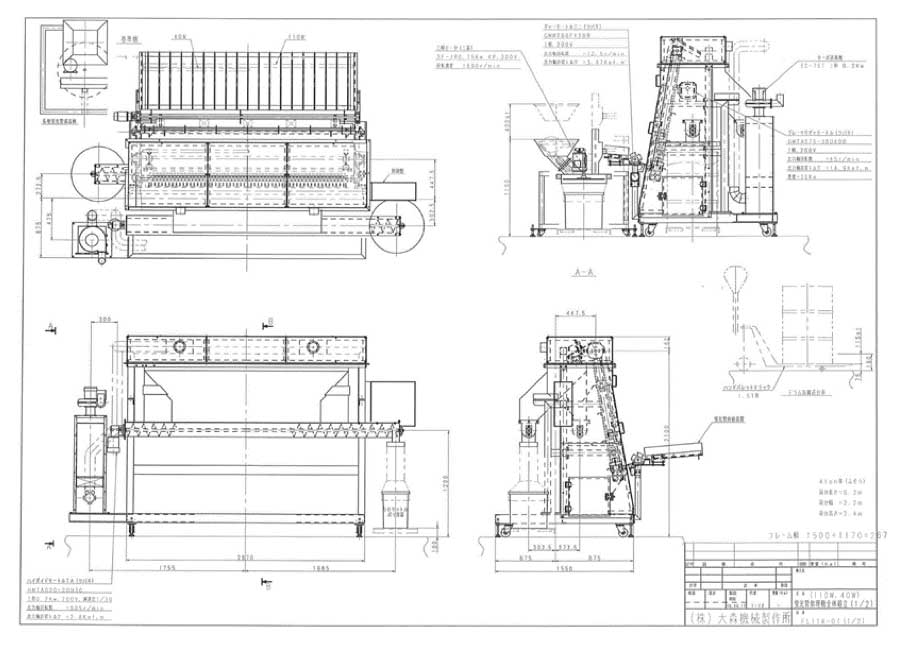

Outline drawing

Specifications

| Types of fluorescent tubes | 40W / 110W straight tubes |

|---|---|

| Capacity | 1,500 pieces/hour |

| Dimensions | W: 3,600 x D: 2,400 x H: 2,300 |

| Weight | 1,500Kg |

| Power source | 200V 15A |

Initial investment

| Standard price | JPY ¥6,500,000 |

|---|---|

| Customization (optional) | For details, please contact us. |

| Installation (optional) | For details, please contact us. |

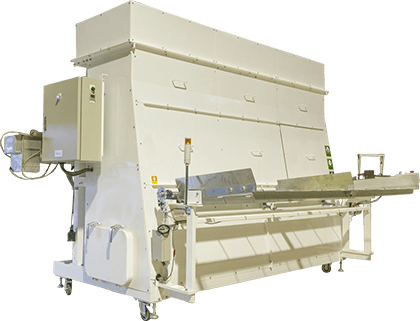

TOPCLEAN Type-2 - 40W WASTE FLUORESCENT TUBES SHREDDING EQUIPMENT

This type of equipment is dedicated to the straight-type 40W fluorescent tubes. Despite its smaller capacity of 1,000 pieces per hour than the 40W/110W type as above, it can separate glass pieces and mouthpieces as well as contribute to saving space with its compact size.

Main features

Separated shredding of glass pieces and mouthpieces with the capacity of 1,000 pieces/hour

Same as the 40W/110W type, the equipment shredded straight-type 40W fluorescent tubes into glass pieces and mouthpieces and send to different containers. Eliminating manual operations will ensure both environmental and operational safety.

It is also equipped with similar features as the 40W/110W type, including an in-built dust collector which collects dust caused by shredding, absorbs with a filter and active carbon and discharges to the air eventually, as well as outlet covers which ensure any glass covers and mouthpieces separated should not be scattered *2.

In addition to the above, it demonstrates high-speed operations, 1,000 pieces (or 250 kg) per hour as well as high durability.

*2 In the photos posted on this website, these covers may be removed so that you can see the detailed parts of the equipment.

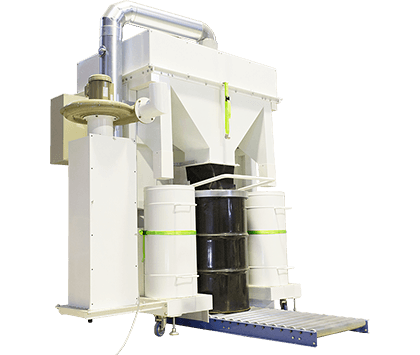

Easy operation and compact size

One of the major factors to significantly worsen operational efficiency in shredding waste fluorescent tubes is to change or move large and heavy containers where shredded glass pieces and mouthpieces are collected. To solve this, our product can be installed over a roller rail, whereby the containers can be moved and changed even by one operator.

In addition, limiting the capacity to 40W fluorescent tubes achieves a compact size (a smaller width by 1,200 mm than the 40W/110W type), which contributes in saving the installation space.

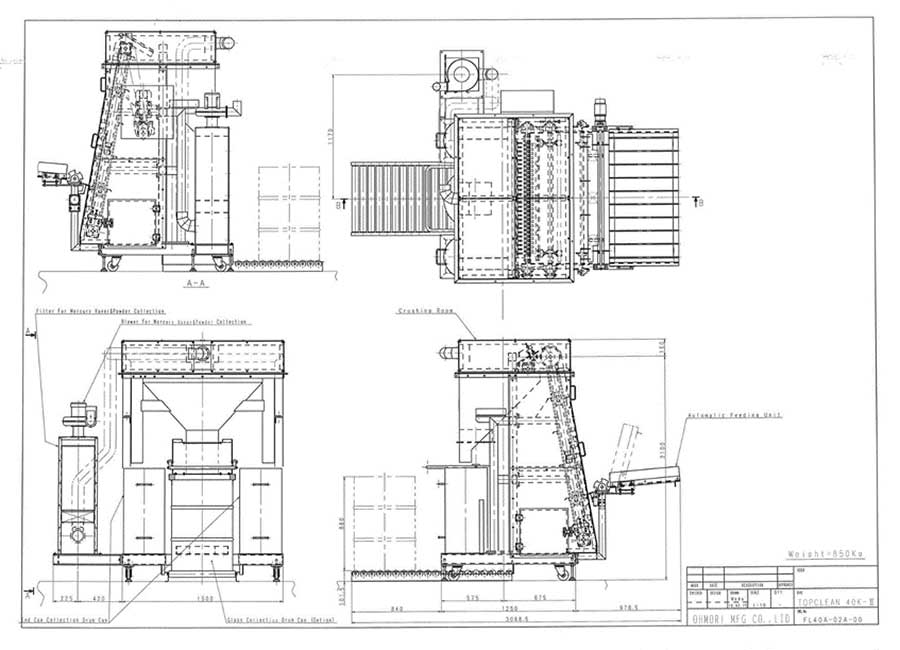

Outline drawing

Specifications

| Types of fluorescent tubes | 40W straight tubes |

|---|---|

| Capacity | 1,000 pieces/hour |

| Dimensions | W: 2,400 x D: 2,800 x H: 2,600 |

| Weight | 850Kg |

| Power source | 200V 15A |

Initial investment

| Standard price | JPY 3,500,000 |

|---|---|

| Customization (optional) | For details, please contact us. |

| Installation (optional) | For details, please contact us. |

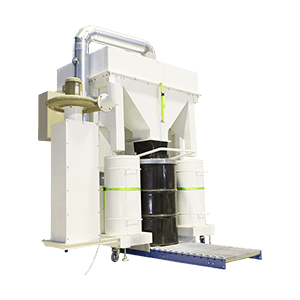

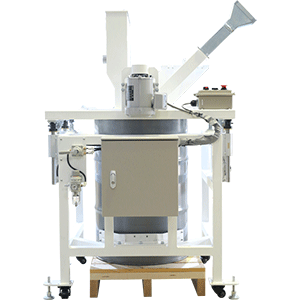

MULTI-SHREDDING EQUIPMENT

There are 300~500 types of “lamps” in Japan. Ideally, they should be disposed of separately in the best way for each type, but this would not be realistic.

This type of equipment can be used for circular tubes, bulbs and any other lamps other than straight tubes (separated shredding is not available).

Main features

Simple and compact

It is easy to operate. All that you have to do is the feed bulbs and circular tubes to their respective dedicated inlets. Containers where shredded glass pieces and mouthpieces are collected may also be installed and moved by using a hand lift.

It uses compact and light equipment which can be moved manually.

Adjusting the shredding level

Bulbs and circular tubes fed from the inlets will be shredded by in-built hammers. It is possible to change the number of hammers to operate (two, three or four). With an inverter, the speed of hammers can be also adjusted.

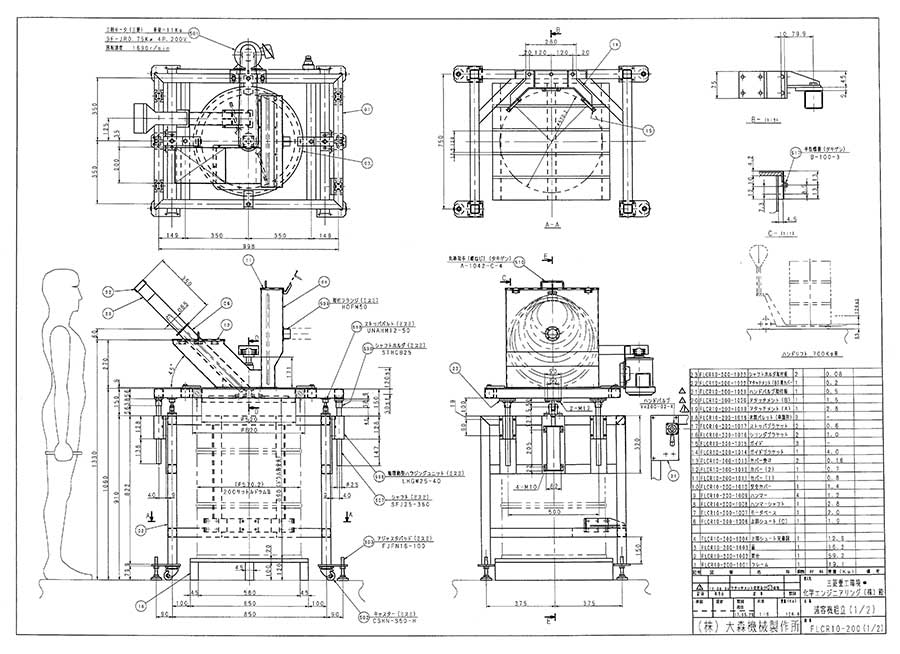

Outline drawing

Specifications

| Types of fluorescent tubes | Circular tubes, Electric bulbs, etc. |

|---|---|

| Capacity | W:1,030 × D:750 × H:1,610 |

| Weight | 300Kg |

| Power source | 200V 15A |

Initial investment

| Standard price | JPY 2,500,000 |

|---|---|

| Customization (optional) | For details, please contact us. |

| Installation (optional) | For details, please contact us. |